Painstaking Lessons Of Tips About How To Build Absorption Chiller

About press copyright contact us creators advertise developers terms privacy policy & safety how youtube works test new features press copyright contact us creators.

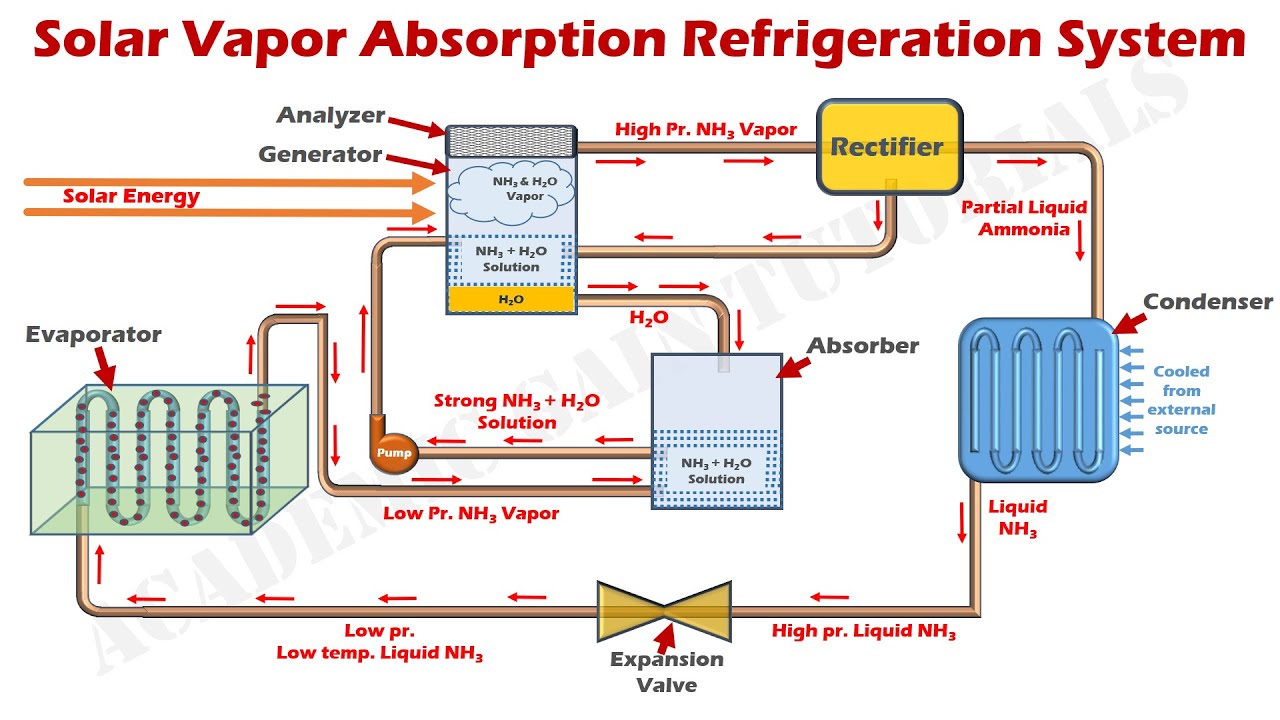

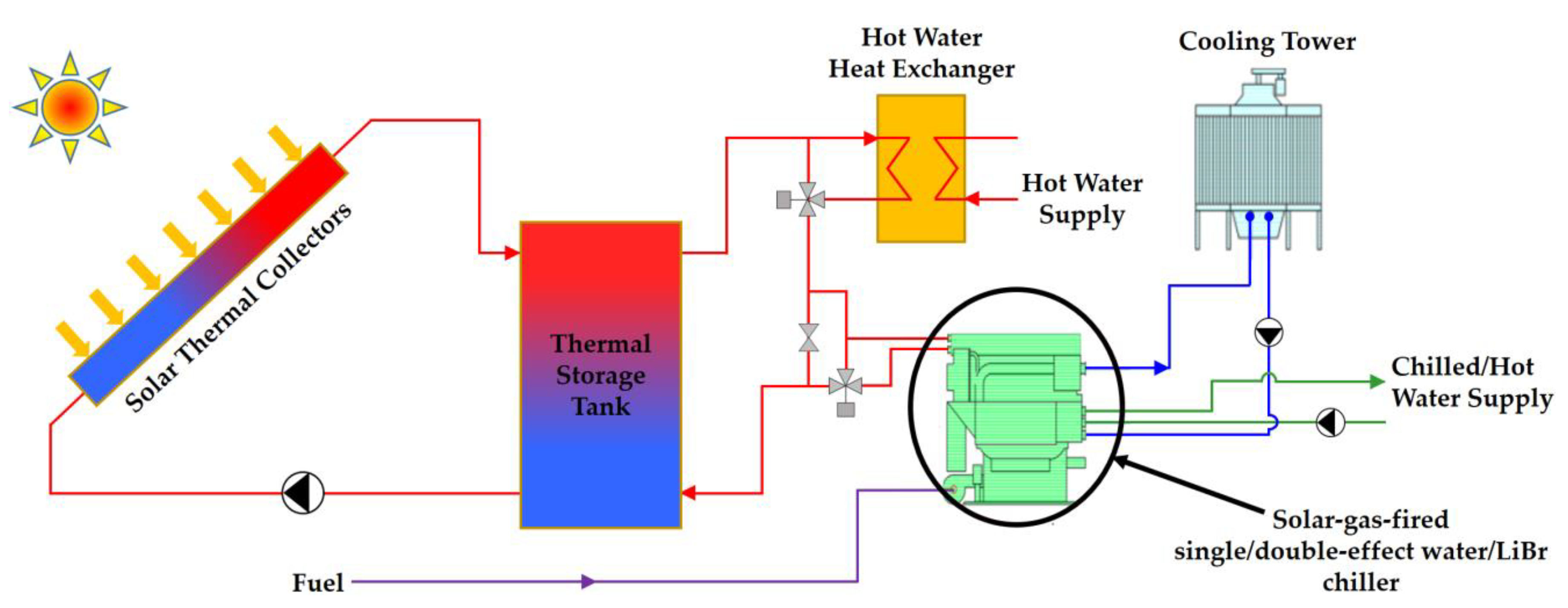

How to build absorption chiller. Absorption chillers rely on heat energy to chill water, so they make a perfect combination with chp systems. Second, it assumes that the cost of natural gas is $4/mmbtu, and electricity is assumed at $0.1 kwh and $0.2 kwh with no demand charge (table 3). Conduct a plant survey to identify sources and availability of waste steam.

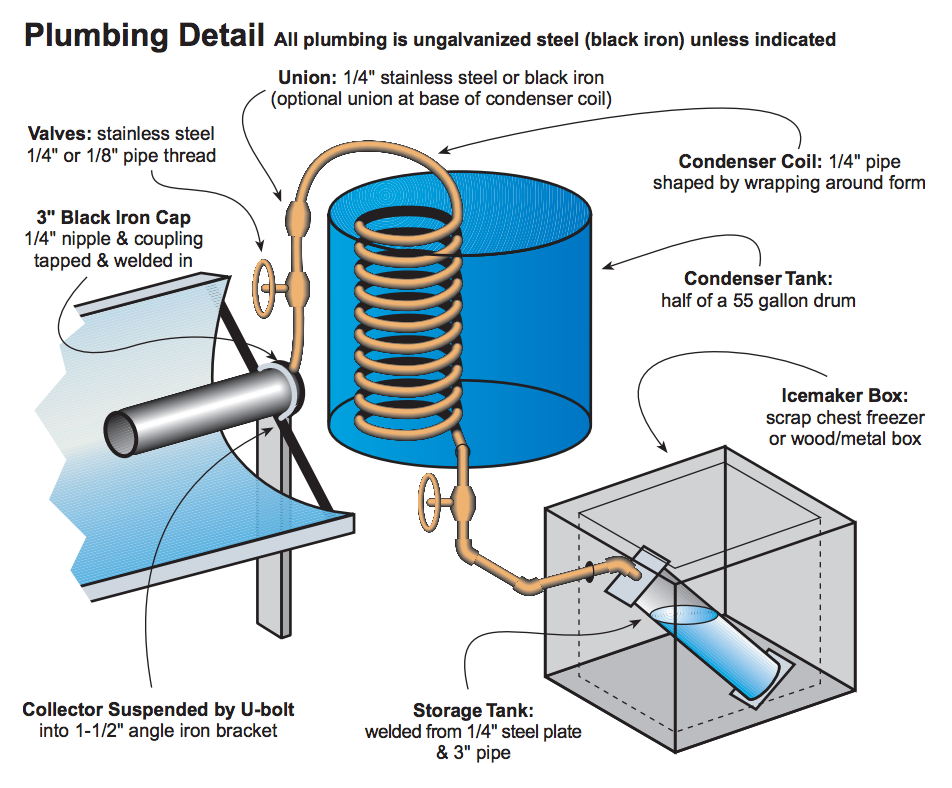

Connect a shorter piece to. The values in figure 6 provide an understanding of. [17] studied the effect of using evaporative cooling and absorption chillers on the power and efficiency of a gas turbine compared with the iso performance.

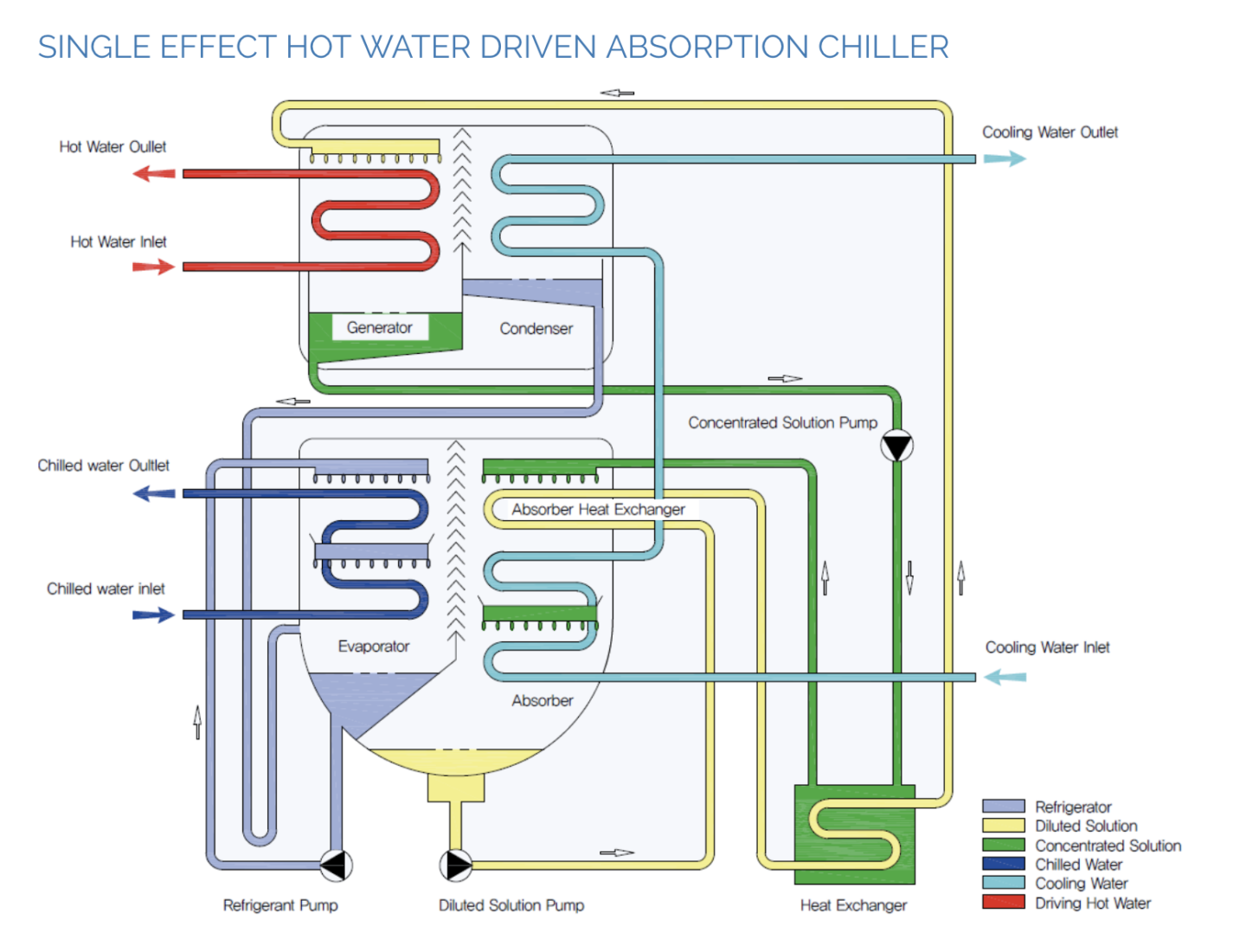

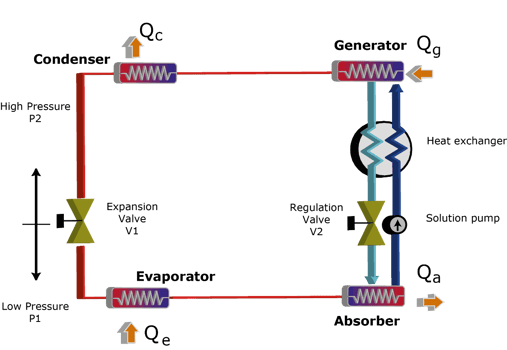

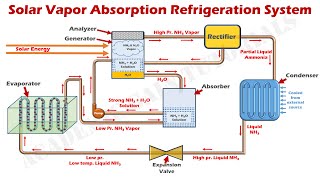

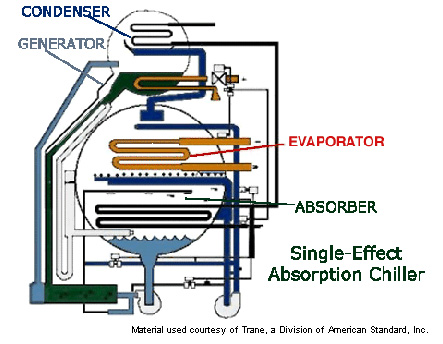

Heat separates lithium bromide and water. The results show that the studied absorption chiller can meet about 65% of the total cooling load of the building with an average cop th of about 0.61. Water steadily evaporates and rises to the condenser, while lithium bromide sinks.

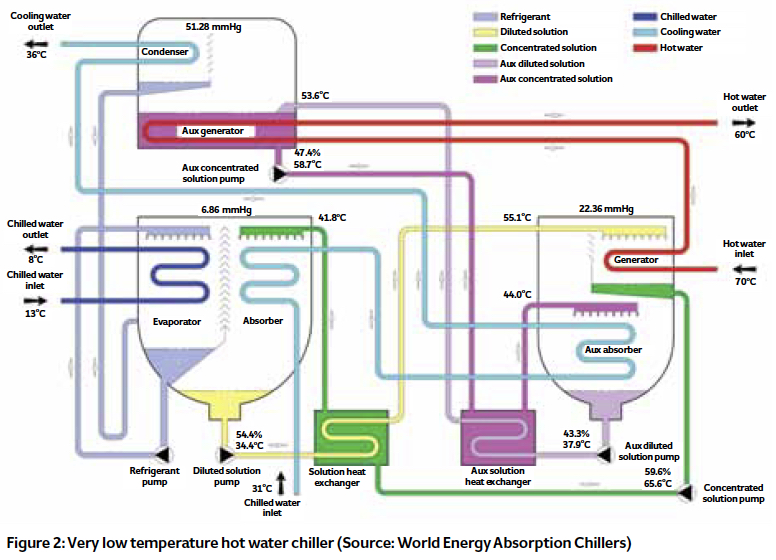

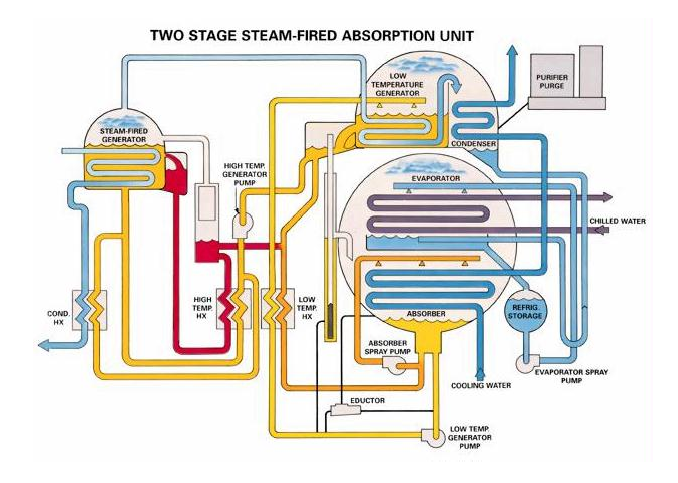

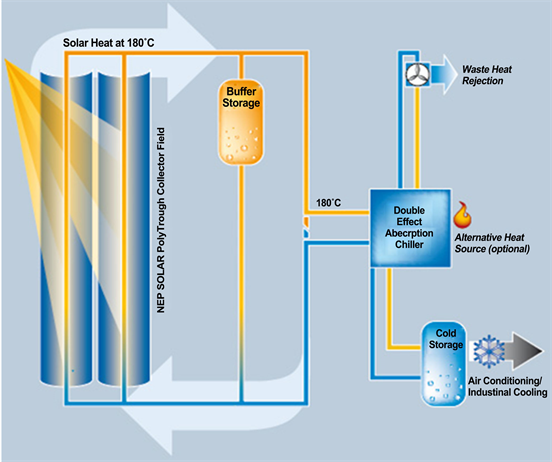

We can model the absorption chiller by considering the energy balance in the four. This installation consists of two 415 kw reciprocating engine generators and an absorption chiller that produces 160 tons of 25°f. Who am i?finding my way across 6300 installations in 96 countries, i have been optimising energy use and slashing carbon pollution for more than three decade.

The designing process starts with the consultation. The table reveals that, at. Absorption chillers typically require a larger cooling tower compared to a mechanical chiller with the same capacity.

The lithium bromide will return to the absorber. Determine cooling load requirements and the cost of meeting. Absorption chiller by taking the following steps: